by Wolfgang Ernst (company datec GmbH), May 2021

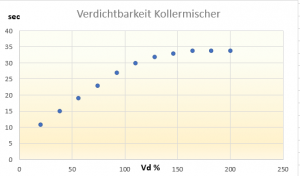

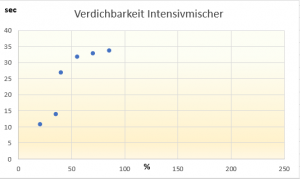

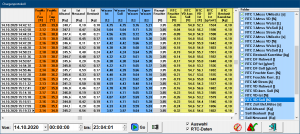

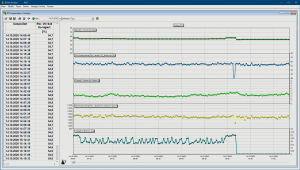

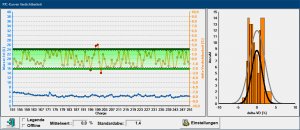

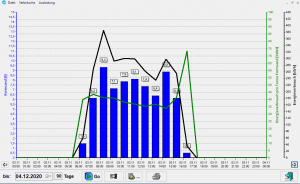

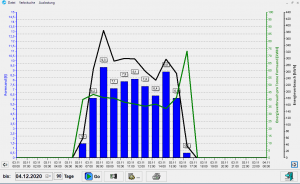

A classic pan grinder with its heavy and large iron wheels requires up to four or even five times the mixing time of an intensive mixer - i.e. about six to eight minutes - for proper preparation. The temporal behaviour of the development of the compaction values was of interest here as a control behaviour adjustment parameter. With the aid of a tool that draws one sample after the other every 20 seconds for the entire mixing cycle, it can be seen that a pan mixer needs up to 3 minutes after the addition of water to achieve 35 % compaction, while an intensive mixer reaches the final value in about 30 seconds. The two diagrams show the different behaviour. "We were surprised, but the GISAG mixer does its job and produces good sand. In addition, we now see much more precisely how the mixer works and how the moulding material reacts and develops during mixing. We have more transparency in the mixing process." Hendrik Schuster, Head of Quality Assurance (B)

Energy efficiency control

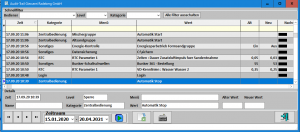

The energy efficiency control programme plays a special role by switching off sand preparation in part or in its entirety and automatically starting it up when sand is needed again. Analogue laser level sensors accurately detect the fill level. Switch-off thresholds, which can be changed via the menu, allow for precise switching off and triggering of the sand supply. "We have simply taken a step forward in terms of ISO 50001. We now record the specific energy consumption in sand preparation and have a core parameter for evaluation, kWh per tonne of moulding sand. We can see pretty much exactly where we stand," Dirk Reinke points out, referring specifically to this control module. "With this retrofit measure, which only affects the control system, we have significantly modernised our sand processing plant and it has no need to fear comparison."

You will find more information about our retrofit here.

You will find more information about our sand testing system RTC 107 here.

You will find more information about our Shake-out_Cooling here.

You will find more information about our energy efficiency control here.

You will find more information about the company Gießerei Radeberg GmbH here.