Operational data acquisition and analysis

Recording, documentation and storage of your production data

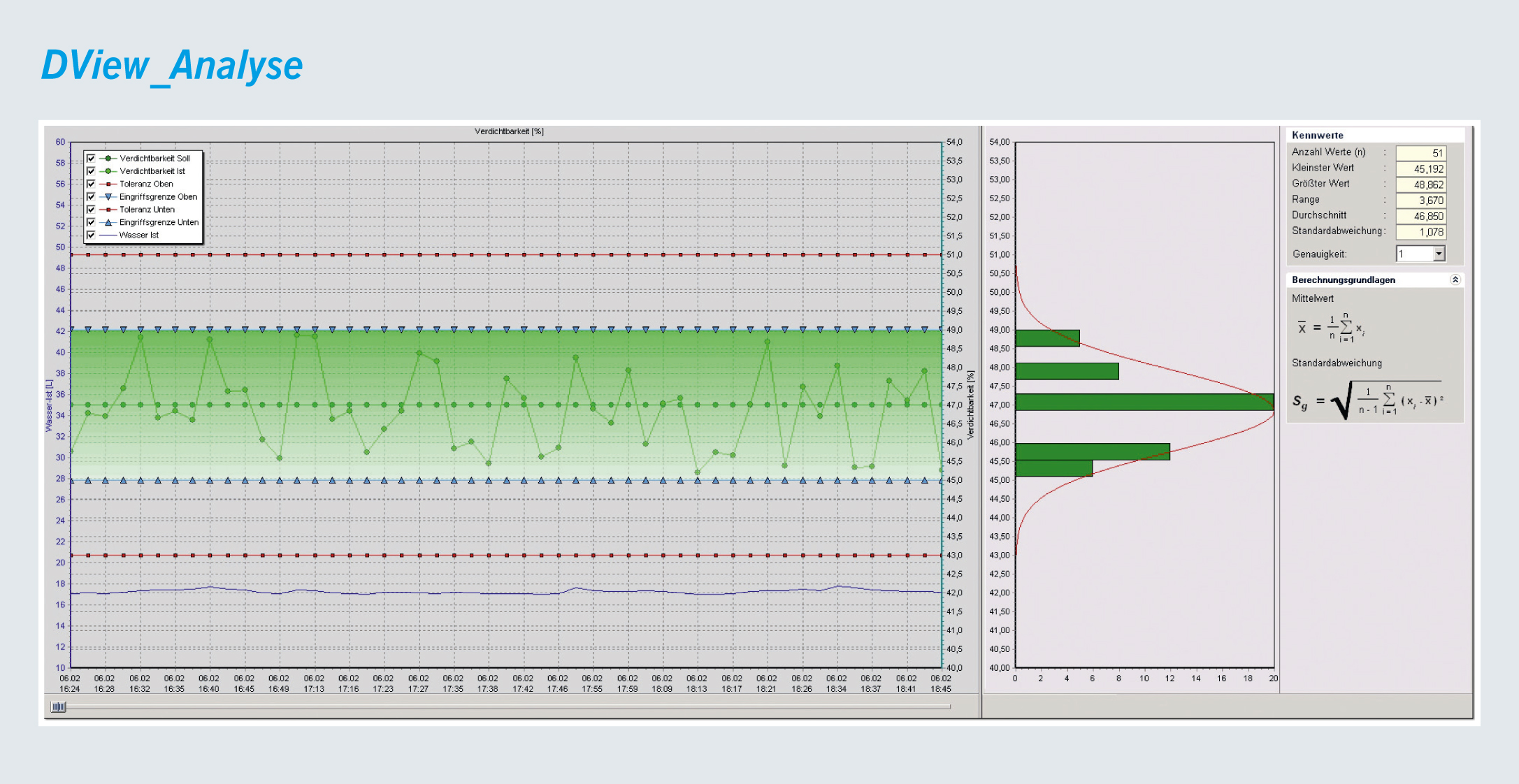

Data transparency

All measurement and control data in the mixing and cooling process are continuously documented

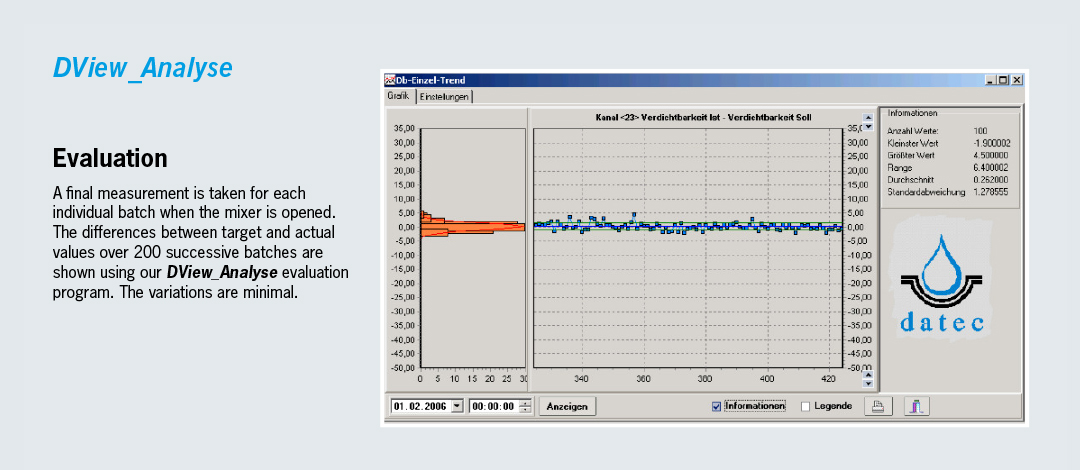

Evaluation

This data can be used for a subsequent evaluation

SPC – statistical process control

The data flood is reduced to central characteristic values by using the methods of static evaluation and thus allows an assessment of the processes

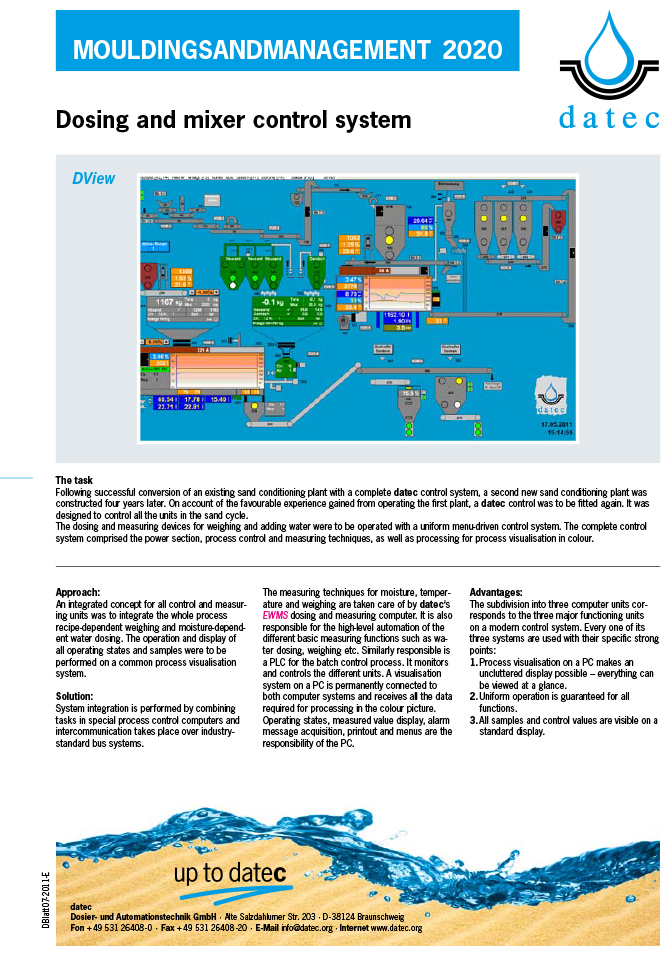

Ethernet connection

The operating data and the operation status are monitored and documented online.

Monitoring

A precise control of processes requires data and evaluation tools

Task

For an automatic production planning system (PPS) the data of every stage of production from all plant componants has to be reported back constantly. For further disposal and controlling tasks, production orders are to be traced within its continuation contemporary.

Approach

The data from the control of each plant / machine are collected and sent to the central control. There the received data is filed for further processing. In this case, the advantage is used, that within each control the relevant data exist in principle or they are able to be traced through the operation status's. They just have to be tapped.

Solution

All independent controls are integrated into a data network, which ends in a technical control centre. Depending on the year of construction, the network capability of existing controls are established with an add-on modul for the PLC. Possible programme supplementing in the control allows the specific record and transfer of the operating data. Using a reader, the order in process is automatically identified and transfered.