Mixer water dosing

akwaplus_mix - Water dosing for your mixer

Temperature resistant process

The right humidification of cold and warm sands

Time-efficient process

No delays inside the mixer

Good accessibility

No measuring devices in the inner part of the mixer: Low wear and easy inspection

Data acquisition via Ethernet

Extensive recording of the measuring data

Clean solution

Self-cleaning moisture electrode

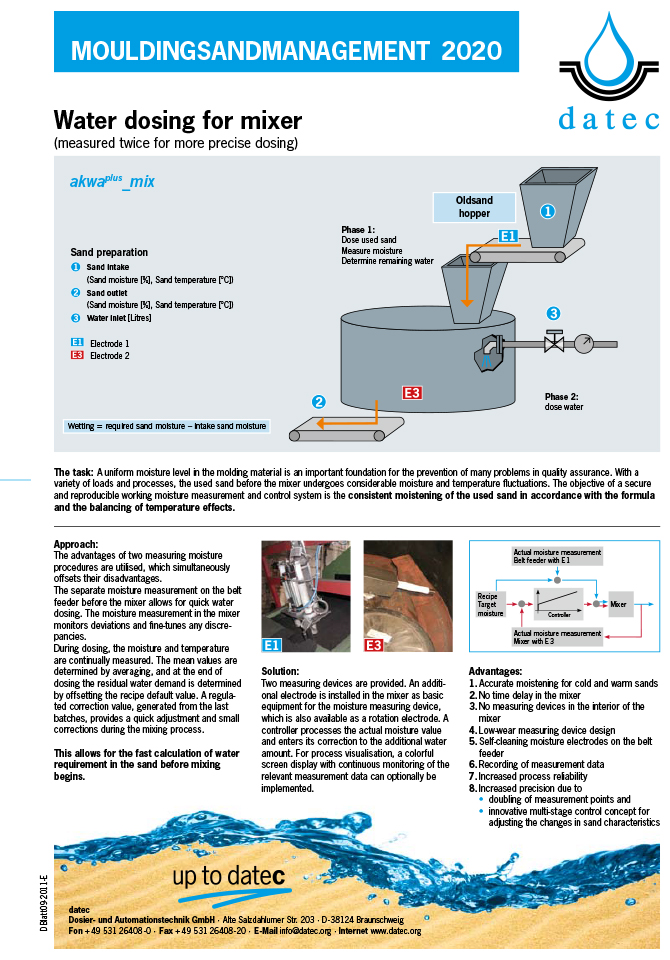

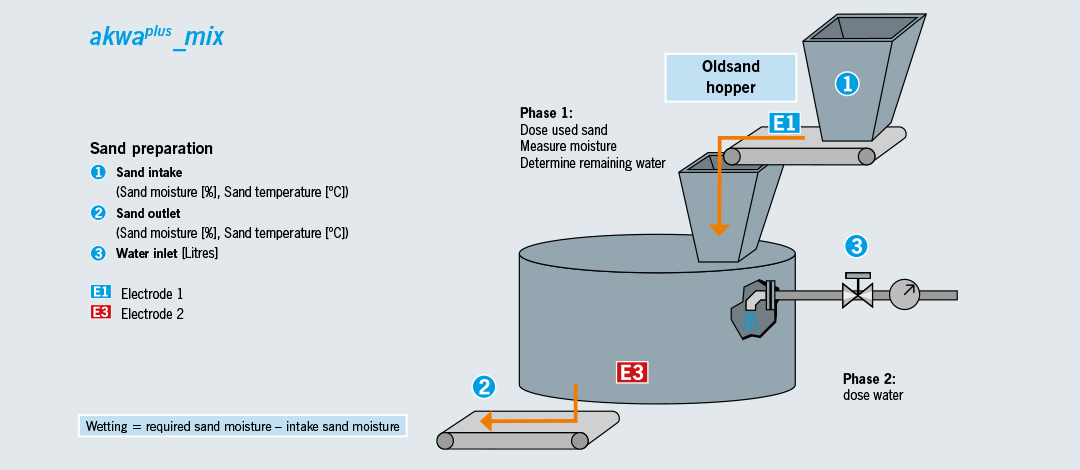

The task

Uniform moisture in the mould material is an important criterion for avoiding a large number of quality assurance problems. Due to the different stresses and processes, however, used sand is subject to considerable moisture and temperature fluctuations before it is mixed. The objective of a reliable moisture measuring and control system which operates with reproducible results is that used sand is uniformly moistened under recipe control and temperature effects are compensated.

Approach

Moisture and temperature are measured continuously during dosing. Average values are determined and, when dosing has finished, the remaining water requirement is established by offsetting the specified recipe value.

This makes it possible quickly to determine the water required in the sand before mixing starts.

Solution

A moisture electrode and a temperature electrode are installed for each discharge belt of the used sand bunkers. By measuring the moisture, the amount of water required to be added to achieve the required value is determined. The temperature specifies the amount of water required to compensate evaporation. The water can be injected when the batch is started. The mixer is not important in this respect, for there is no need to install a measuring device in the mixer. The moisture measuring electrode is self-cleaning in order to avoid the typical contamination effect.