Visualisation

DView - visualisation of your plant

Everything at a glance

Increasing monitoring activity for individual processes is centralised

Synchronous progress

The central process control system keeps pace with the automation progress of the individual plant components

Visualisation in virtual surroundings

System protection for PC, programme and saved data

Task

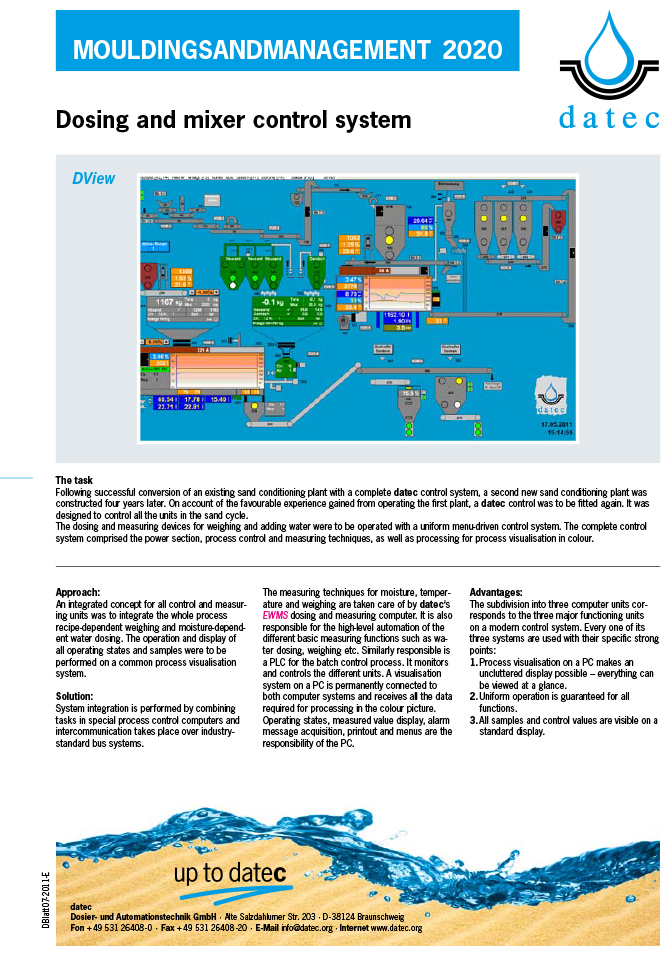

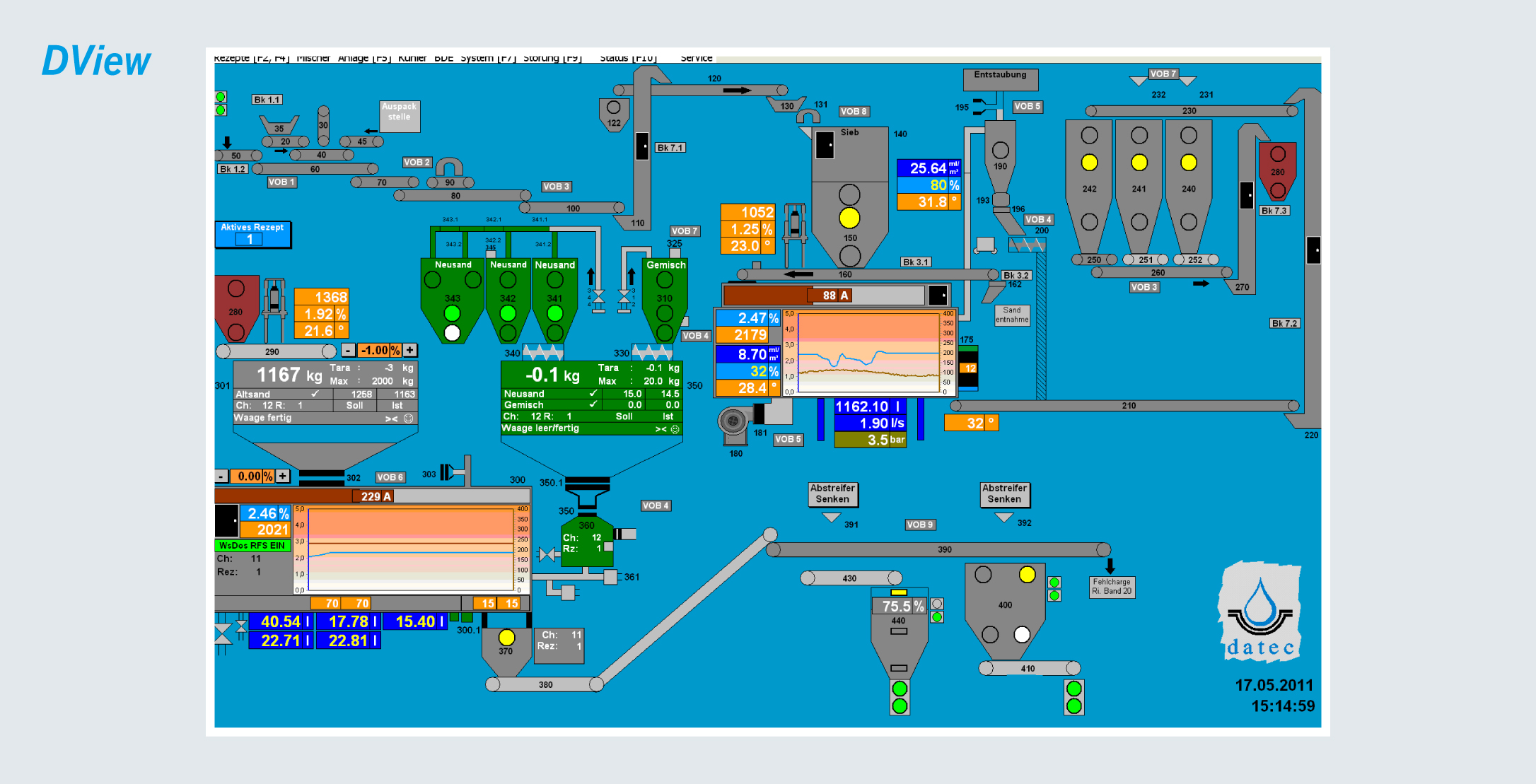

A complete plant should be fully depicted with all its assembly units and the resulting signal states as well as with its measured values. All plant components can be included at a glance.

The complete control system includes the power section, the sequence control up to the measuring technology and preparation for a coloured process visualisation. The relevant batch data must be documented. For the purpose of remote maintenance, the controller and the visualisation must be integrated into the Ethernet network with Internet access.

For the visualisation PC, the programmes and the data which need to be secure should not be held on site.

Approach

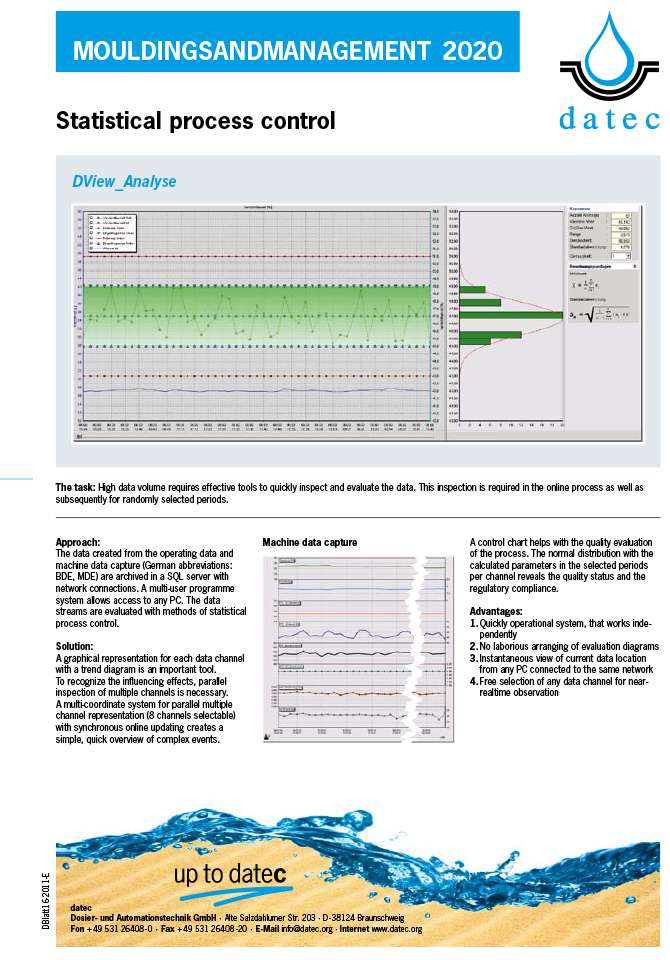

An integrated design for all elements of control and measurement should summarise the overall process, formulation-specific weighing, and moisture-dependent water dosing. Handling and display of all operating statuses and measurement values take place via a common process visualisation system.

Solution

A visualisation system on a computer is in constant connection with the control system and receives all relevant data for preparation in the colour image. Operating states, measured value display, fault message recording, logging and menus are the responsibility of the computer.