Batchcooler control system

Unlock the full potential of your batchcooler with cool_mix

Optimal sand rejuvenation in accordance with your requirements

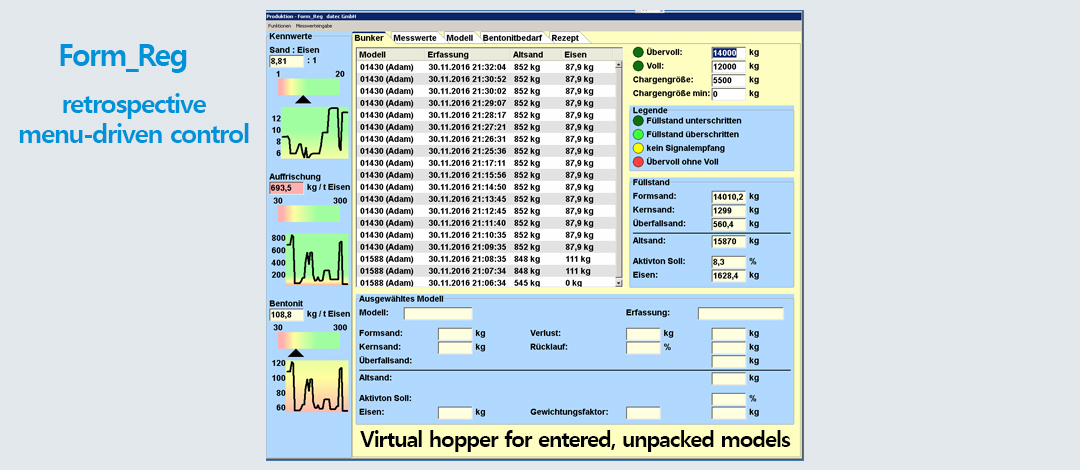

In conjunction with Form_Reg, the wear factors of which determine the quantity of binding agent required

Time-efficient cooling process

Quick cooling

Effective cooling

Cooling possible up to 40° C if the temperature of the surroundings is suitable

Data gathering via the ethernet

Comprehensive logging of the measurement data

Double usage of the cooler

Simultaneous dust-free cooling and dosing of auxiliary materials for casting

Intelligent homogenisation

Optimal processing of used sand to homogenise the overall sand profile

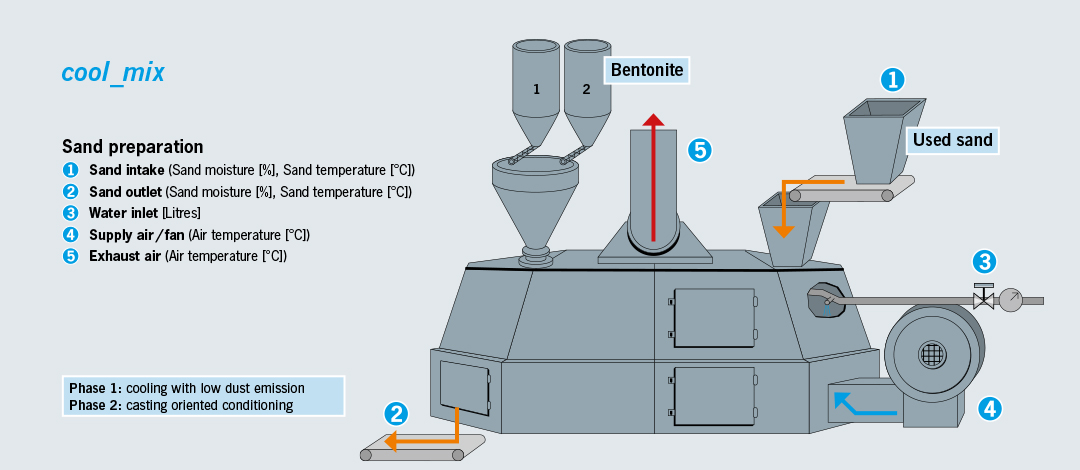

Task

After unpacking, the used sand contaminated by the moulding facilities must be cooled and processed as quickly as possible. At the same time, cooling, dosing of additives as well as mixing must be realised in a batchcooler with mixing tool. The dosing of the additives such as bentonite, GKB and new sand depends on the mould.

Approach

The cool_mix control mode will spice up your batchcooler. The batchcooler with mixing tool is operated in batch mode. Cooling and dosing of the additives takes place sequentially in order to keep the amount of dust low by means of the cooler’s suction. This accomplishes two functions in one aggregate. Thus the old sand is processed as early as possible and the residence time in the old sand bunker is optimally used.

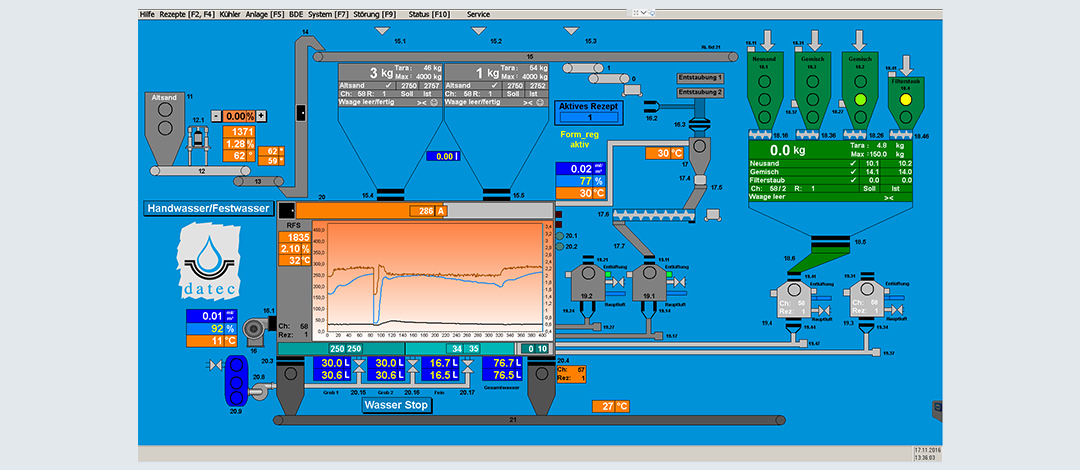

Solution

The cool_mix control mode organises this intelligent process. The batchcooler is supplemented by mixer functions and receives, among other things, a weighing feature, which allows it to operate in batches. The sequential progression of the initial cooling and the subsequent addition of bentonite, the exhaustion of the freshly dosed bentonites can be avoided by cutting of the cooling air supply. Afterwards the freshly conditioned old sand can remain in the bunker for aging purposes and will only need to be brought to its target moisture level in the end mixer.

The dosing of the additives happens via the process of the moulding material balancing with the programme package FORM_REG. For this purpose, the information of the moulding facilities are processed via the moulding programme in order to balance the thermal waste and the dilution caused by the core sand supply.