Preventive menu-driven control

Form_Reg - Preventive menu-driven control for your sand plant

High moulding sand quality

Independent of the sand temperature, the sand is moistured correctly for the cast.

Versatile application

The waterdosage can be equipped for each mixer type and can therefore be used universally.

Ethernet connection

Operational data and the state of operation are monitored and documented online.

Autonomous system

The electrode inside the mixer is in principle self-cleaning and limits the service expenditure.

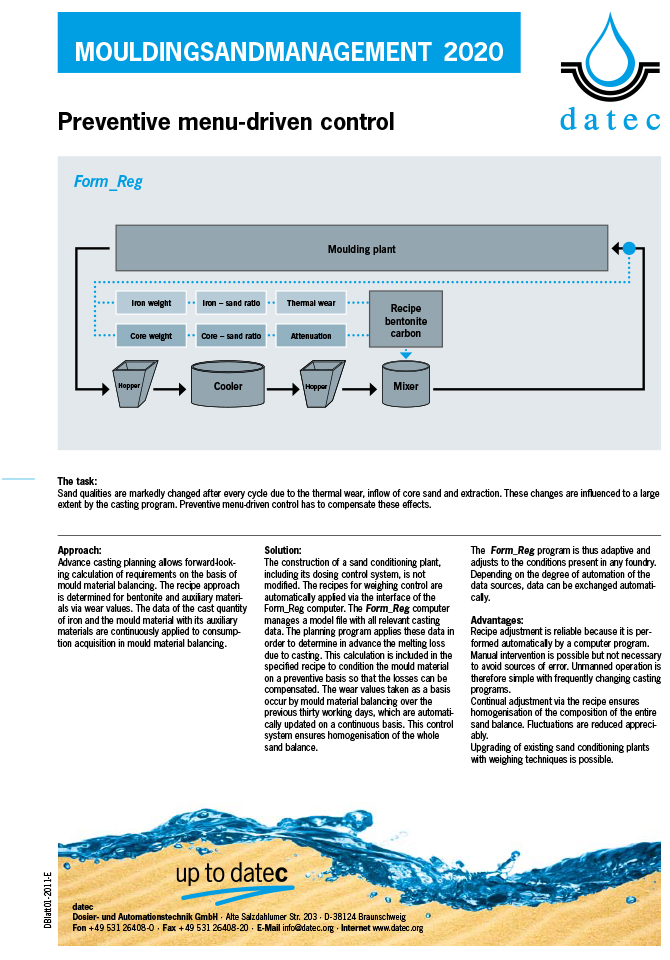

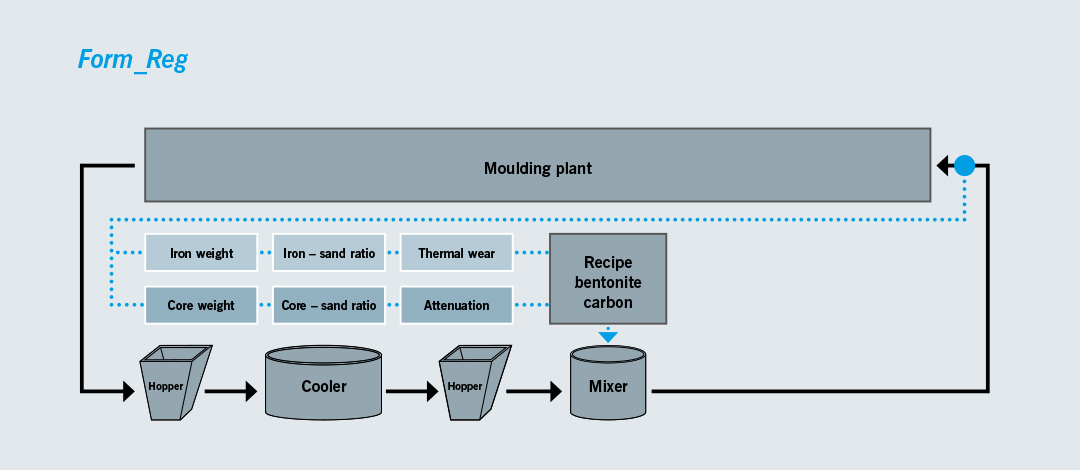

Task

Sand qualities are markedly changed after every cycle due to the thermal wear, inflow of core sand and extraction. These changes are influenced to a large extent by the casting programme. Preventive menu-driven control has to compensate these effects.

Approach

Advance casting planning allows forwardlooking calculation of requirements on the basis of mould material balancing. The recipe approach is determined for bentonite and auxiliary materials via wear values. The data of the cast quantity of iron and the mould material with its auxiliary materials are continuously applied to consumption acquisition in mould material balancing.

Solution

The construction of a sand conditioning plant, including its dosing control system, is not modified. The recipes for weighing control are automatically applied via the interface of the FORM_REG computer. The FORM_REG computer manages a model file with all relevant casting data. The planning programme applies these data in order to determine in advance the melting loss due to casting. This calculation is included in the specified recipe to condition the mould material on a preventive basis so that the losses can be compensated. The wear values taken as a basis occur by mould material balancing over the previous thirty working days, which are automatically updated on a continuous basis. This control system ensures homogenisation of the whole sand balance.

The FORM_REG program is thus adaptive and adjusts to the conditions present in any foundry. Depending on the degree of automation of the data sources, data can be exchanged automatically.