What to do when the used sand cooler can no longer do the job properly?

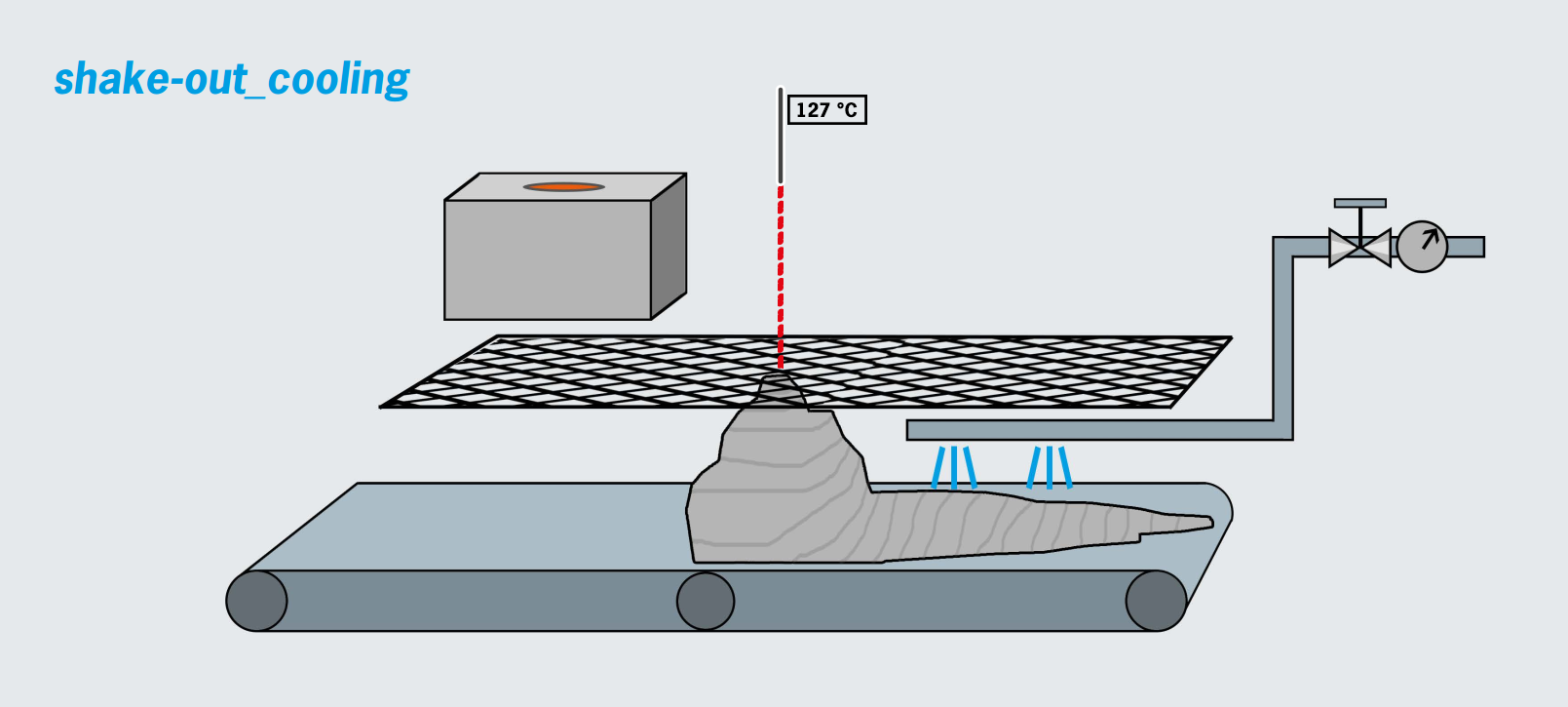

shake-out_cooling - Pre-cooling at the shake-out

Elimination of temperature peaks

Adapted and controlled water addition

Cost-effective - with low installation and set-up costs

Task

Due to the constantly increasing quantities of cast iron in the unpacked used sand, the temperature values rise and thus make sufficient cooling of the moulding sand on the way to the moulding plant more difficult. Coolers are increasingly reaching their limits and can no longer cool down adequately. Temperature peaks in particular cause unpleasant outliers.

Even aluminium foundries are increasingly confronted with higher used sand temperatures and do not want to invest in a used sand cooler.

Approach

Temperature peaks in the recently unpacked used sand must be cut early before the cooler. Then the cooler can cool down again to acceptable used sand temperatures. Pre-cooling immediately in the enclosed unpacking point with its own enclosure is an effective, earlier point in time.

Solution

A simple but highly effective cooling method is the targeted addition of water immediately after the sand-iron separation, when the used sand falls, after being ejected, through the sieve onto the transporting belt. The evaporation of water is a highly energy-intensive process in which the heat energy is extracted from the sand. Air is then extracted with the evaporation via the extraction system in the packing house. The amount of water is determined according to the temperature measurement and the amount of sand just pressed out of the moulding box. Water is only sprayed onto the sand bed when the temperatures have exceeded an adjustable limit value and the quantity of water is adjusted according to the target temperature. Additional control functions ensure proper operation in order to prevent excessive water additions.

Advantages

1. Eliminates the unpleasant temperature peaks in the used sand and relieves the cooler

2. Lowers the temperature level in the sand circuit

3. Adjusted and controlled water addition

4. No wear of the temperature probe due to non-contact measurement

5. Flexible adjustment of the working area for the cooling

6. A system with a cost-effective price ratio and low installation and set-up costs

Please feel free to contact us.

You can either send us an email to info@datec.org or call us at +49 (0) 531 / 26 40 80.