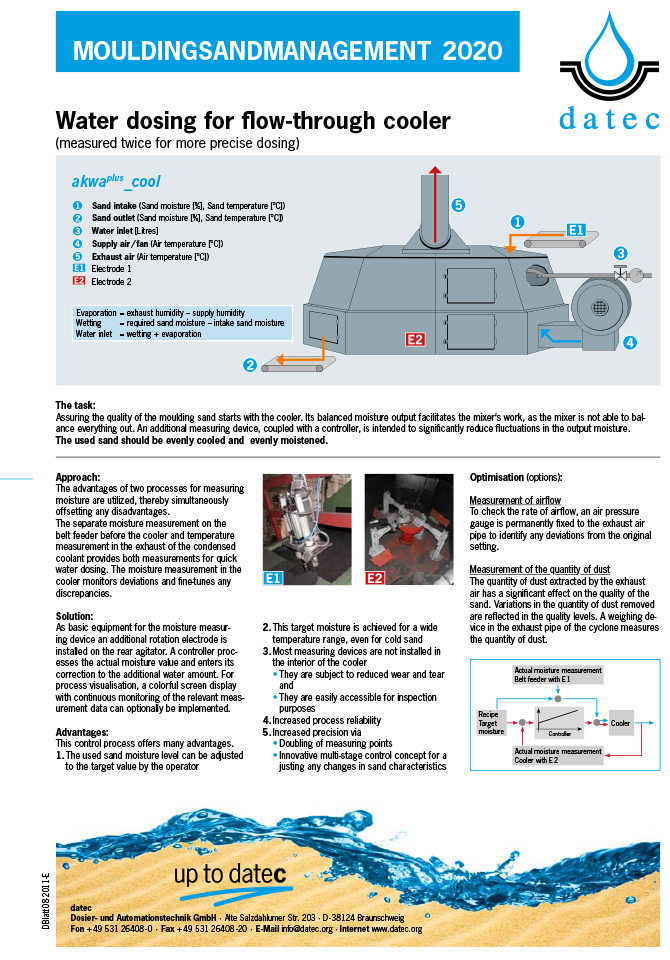

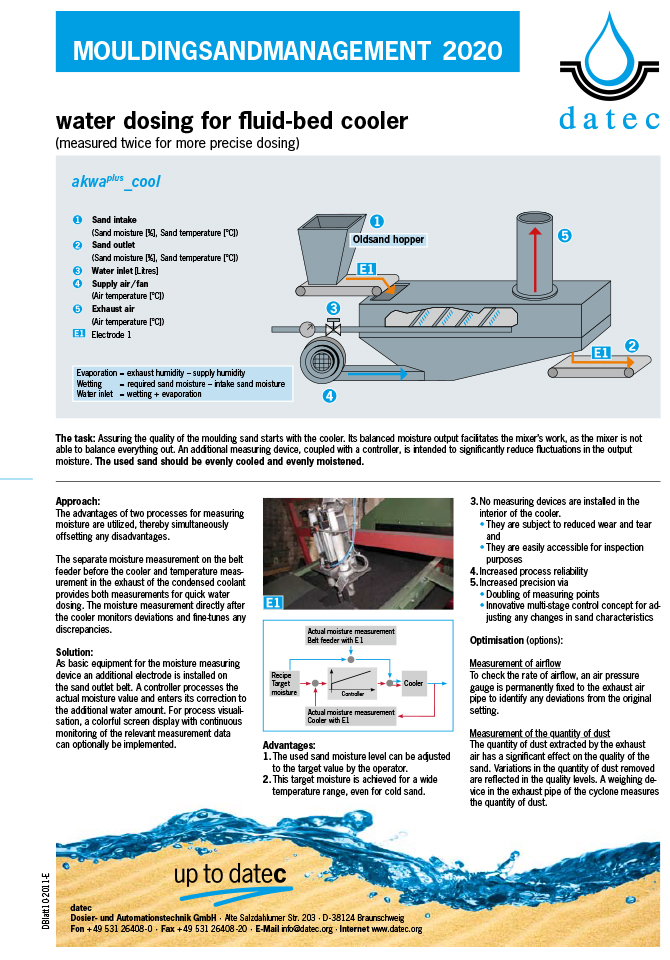

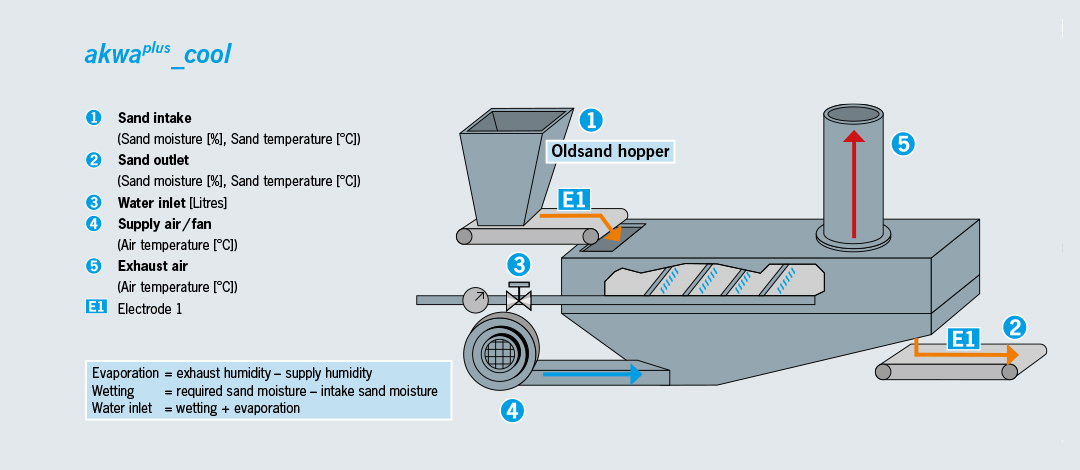

Fluid-bed cooler water dosing

akwa_cool - Water dosing for your fluid-bed cooler

Perfect cooling effects

Demand-driven water addition for cooling and Aufnetzung

Low-wear measurement

The necessary measurements are not installed inside the cooler, therefore they show low wear and are easily accessible for inspection purposes

Task

High-temperature moulding sand (50 °C or more) causes a number of problems when it is processed in the moulding plant. The moulding sand dries on the surface and condensation forms in large concentrations on the core surface. These effects result to a large extent in casting defects, which later have to be compensated at considerable time and effort. When using shake-out drums, the return sand has to be cooled down efficiently subsequent to shake-out. A further objective is adequate pre-wetting in order to allow the important maturing process to start during storage in the bunkers. The objective with regard to used sand conditioning in the drum is:

the used sand is required to be cooled uniformly and and moistened uniformly.

Approach

The cooling method used is evaporative cooling. The evaporation of water in air is very energy-intensive. This energy is derived from the thermal energy present in the used sand. This extraction of energy is primarily responsible for cooling. The art of water dosing consists in adding the proper amount of water. Two major effects cause fluctuations: the ability of the air to absorb water, which is a function of temperature, and the water required by the sand to wet it up to its required value. Two measuring groups are used for these effects. They cover the evaporated water in the air and the water required in the sand.

Solution

Both water components are acquired separately by measurements. The evaporated quantity of water is obtained from measurements for determining the humidity in the supply air and exhaust air. The remaining quantity of water for reaching the required moisture is determined by measuring the moisture in the used sand upstream of the drum. Both components together provide the quantity of water which has to be injected; it flows continually via a control valve into the drum. As an option for process visualisation, a colour screen display can be implemented with continuous recording of the important measured data.

Each water inlet has a water meter and is controlled separately using fluid-bed cooler water dosing. In this way, water quantities can be distributed across the individual inlets / nozzle sets. Significant over-wetting of individual areas of sand is avoided.

The optimisation process involves moisture measurement at the exit point via the sand being taken out, in order to determine variances between required and actual values. The system has its own water source which doses the final quantity of water via the last water inlet and ensures that the variance is quickly corrected.