Moisture measurement

akwa_indicat: Precise and robust

Monitoring of measured values

Measurement and temperature display at all points during processing at the moulding

Cleaner Solution

Self-cleaning moisture electrodes

High level of accuracy

High measurement resolution (1/100 % moisture)

Adapted electrodes for various conveyor belts, silo outlets and in the mixer as well as cooler.

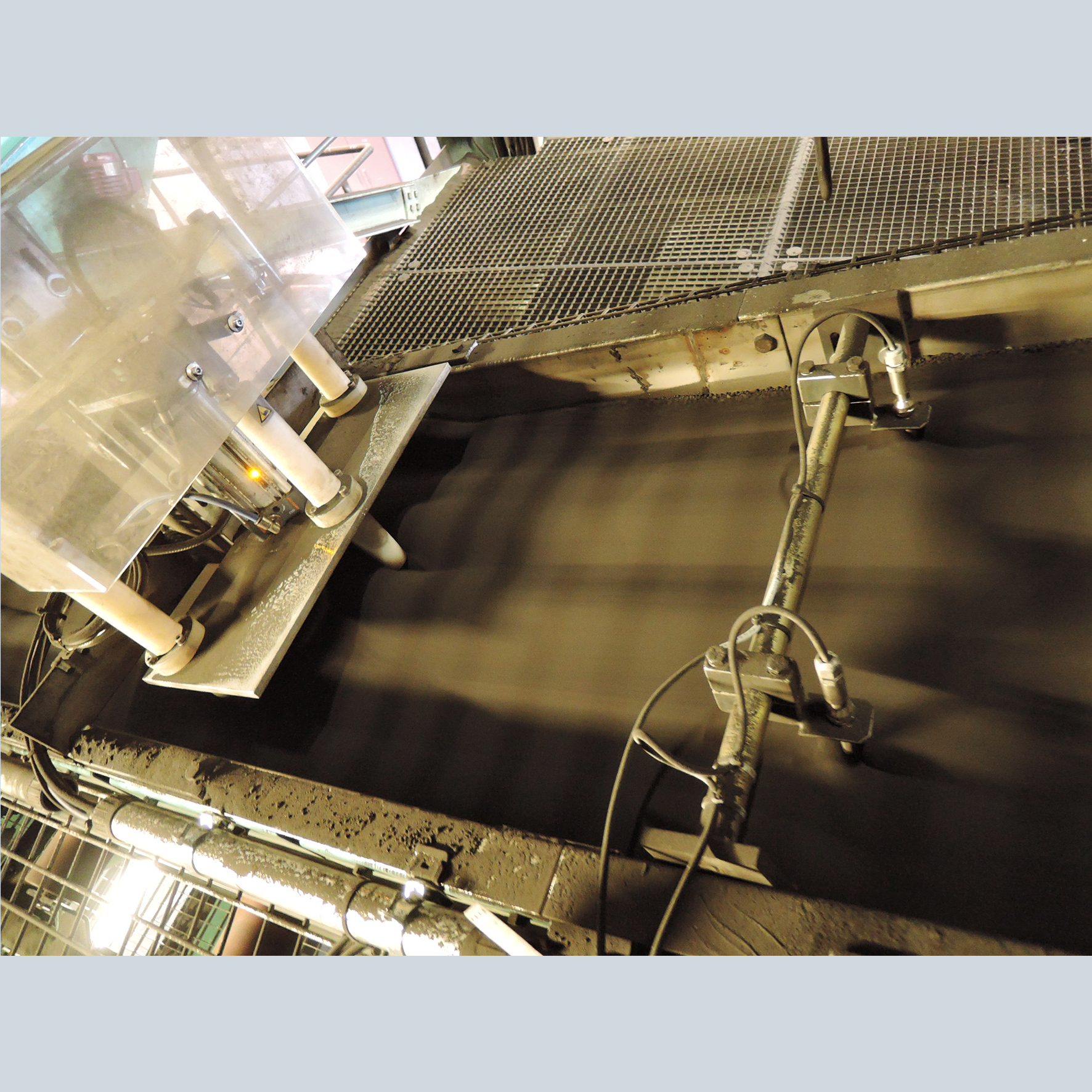

Bipolar moisture measuring electrode FS112 suitable for measurement in the mass flow above the silo outlet and suitable for measurements on belts with a sand bed width between 200 and 450 mm

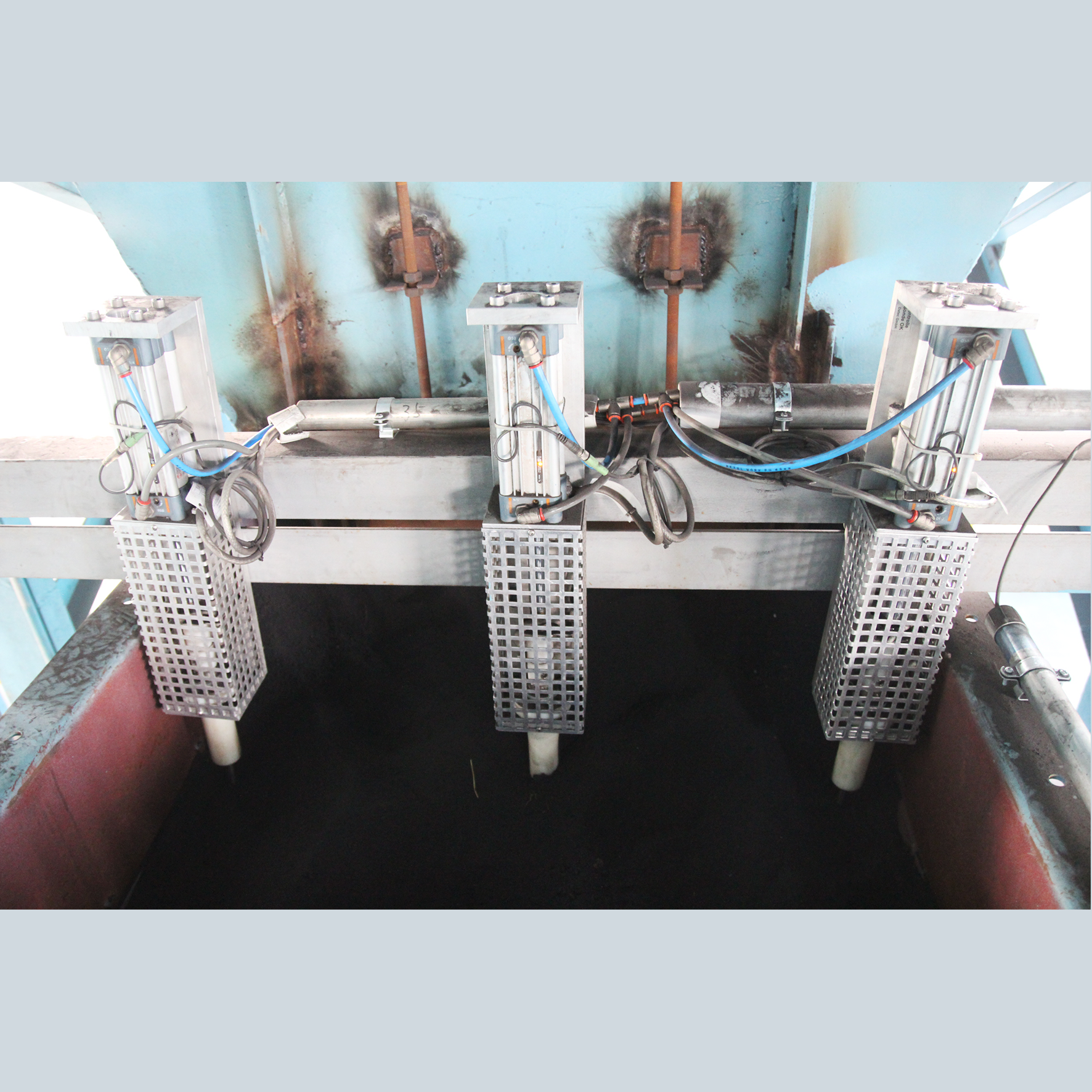

Tripolar electrodes for sand bed widths:

- TFS 141.250 (between 450 and 600 mm),

- TFS 141.400 (between 600 and 750 mm) and

- TSF 141.550 (between 750 and 950 mm)

3 MFS monopolar moisture electrodes for variable sand bed widths more than 1000 mm

Each electrode is self-cleaning - electro-pneumatically controlled and has a terminal box FK 185 per moisture measuring point

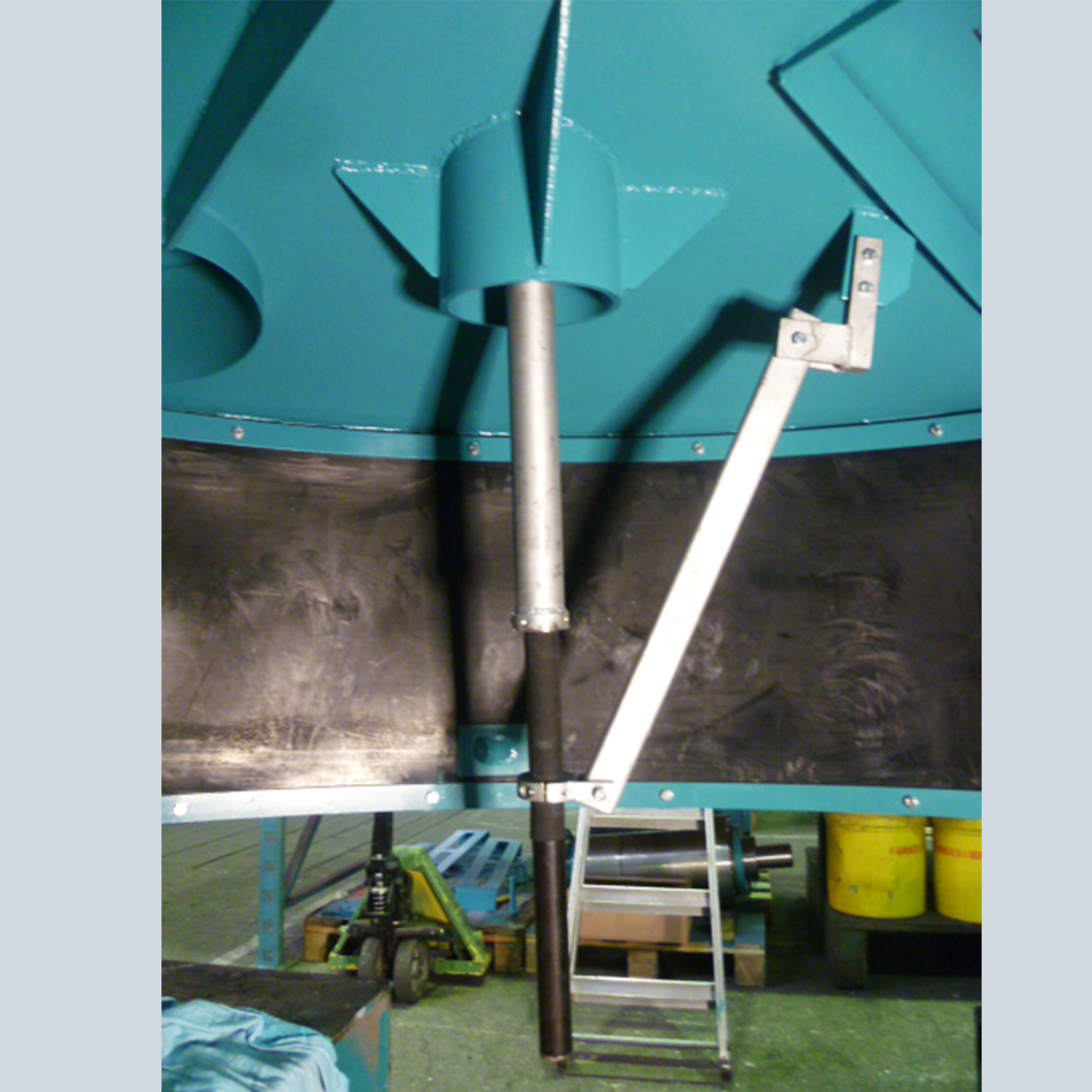

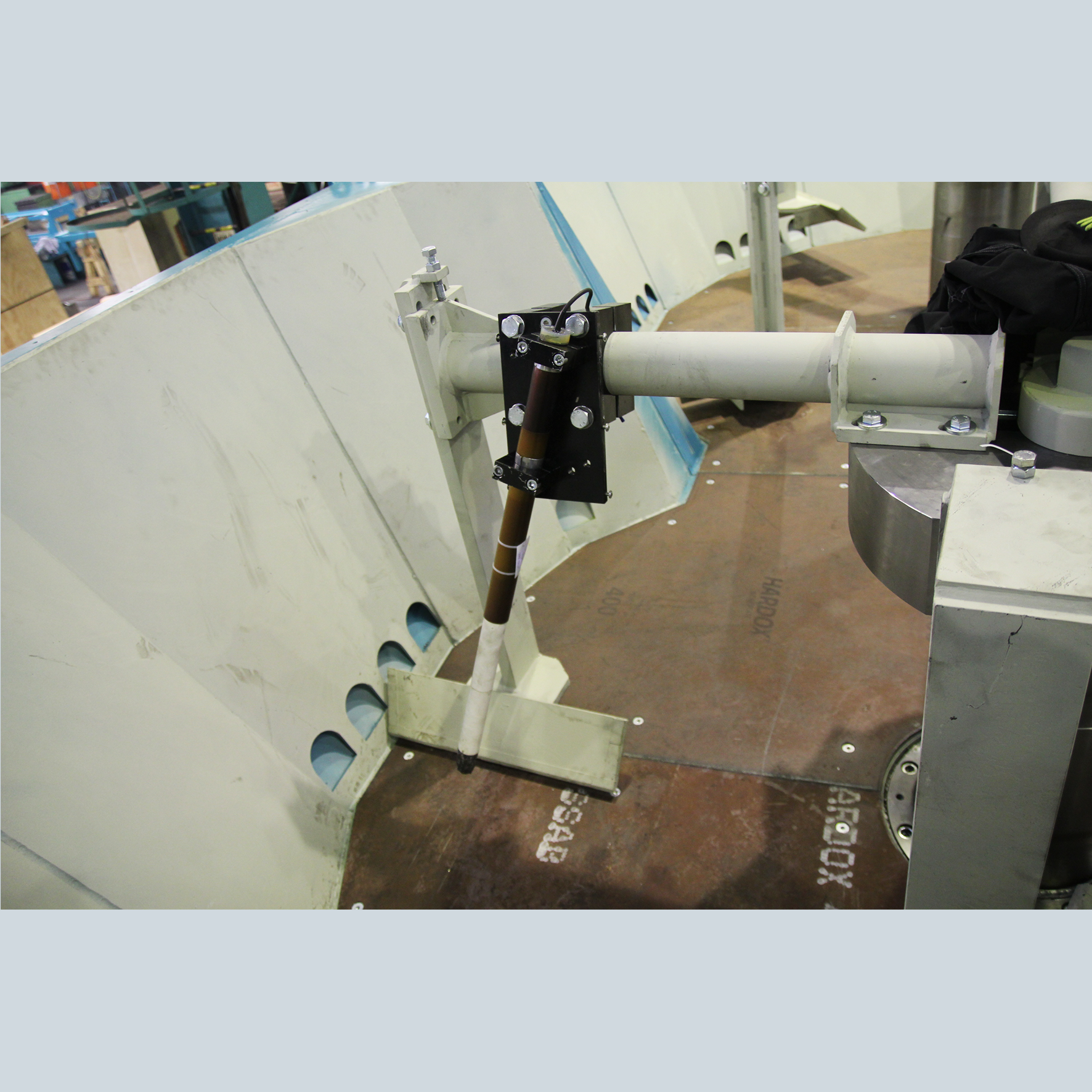

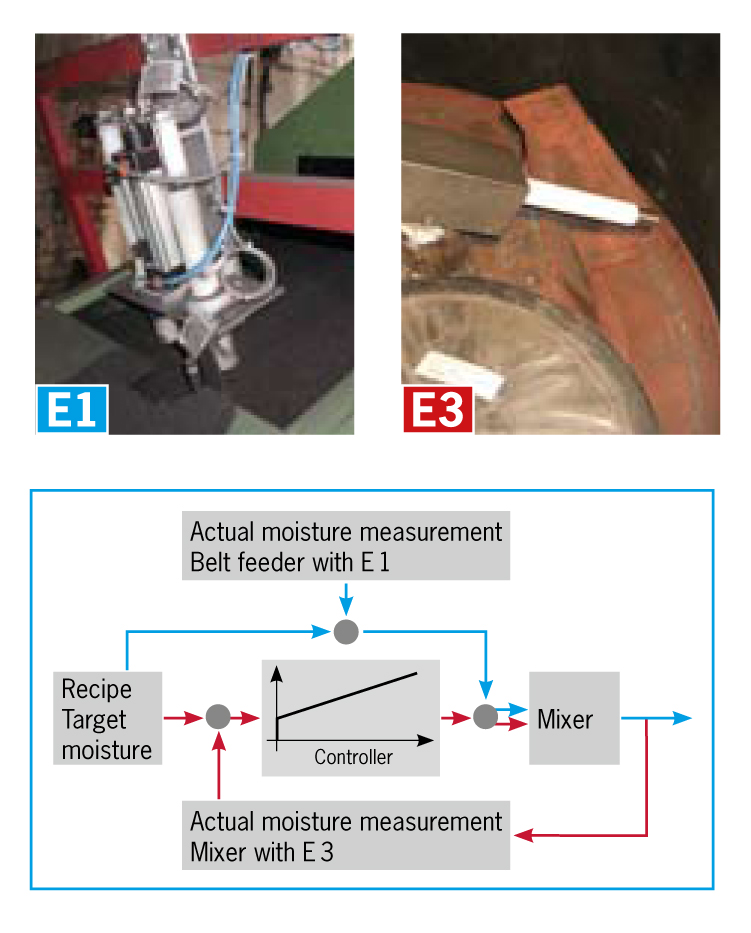

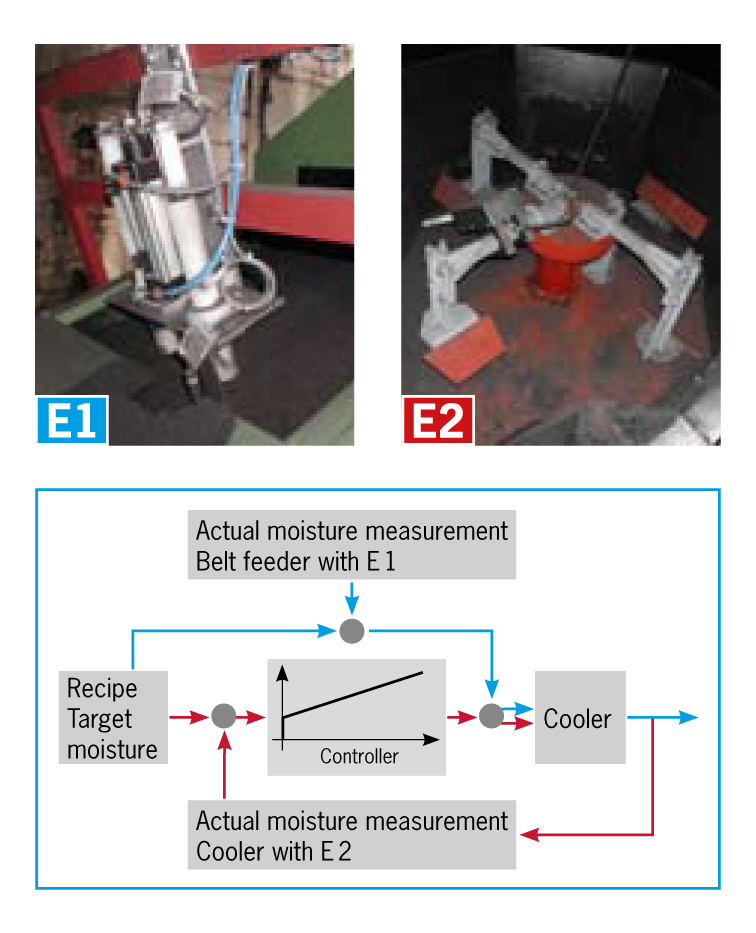

Electrodes for mixers and coolers

The installation possibilities vary greatly, since an electrode must always have uniform coverage. A big obstacle are the rotating stirring tools, because they could collide with an incorrectly installed electrode. Consequently, there are different electrode types for different mixer types with corresponding installation locations and holders.

Self-cleaning electrode SFS 121, installed from above through the cover of the housing and fixed with a flange. The stirring tools rotate just above the bottom

Rotating electrode RFS 104 in a speedmullor, rotating with the horizontal muller wheels

RFS 104 rotating electrode in a mixing cooler; the electrode is attached to a stirring arm.

Pre-moisture measurement on the belt before the mixer or cooler

Combination of pre-moisture measurement and measurement in the mixer or cooler for setting up a control loop to compensate for possible moisture differences between recipe setpoint and actual value.

Task

Consistent recording of moisture and temperature in the moulding sand for each box for the purpose of documentation and moisture adjustment.

Approach

Moisture and temperature will be synchronously measured for average determination on the discharge conveyor of the machine bunker at the moulding facilities. Online display of location and data transfer toa computer for long-term recording.

Solution

Please feel free to contact us.

You can either write us an email info@datec.org

or call us +0049 531 26 40 80.