Dust control management

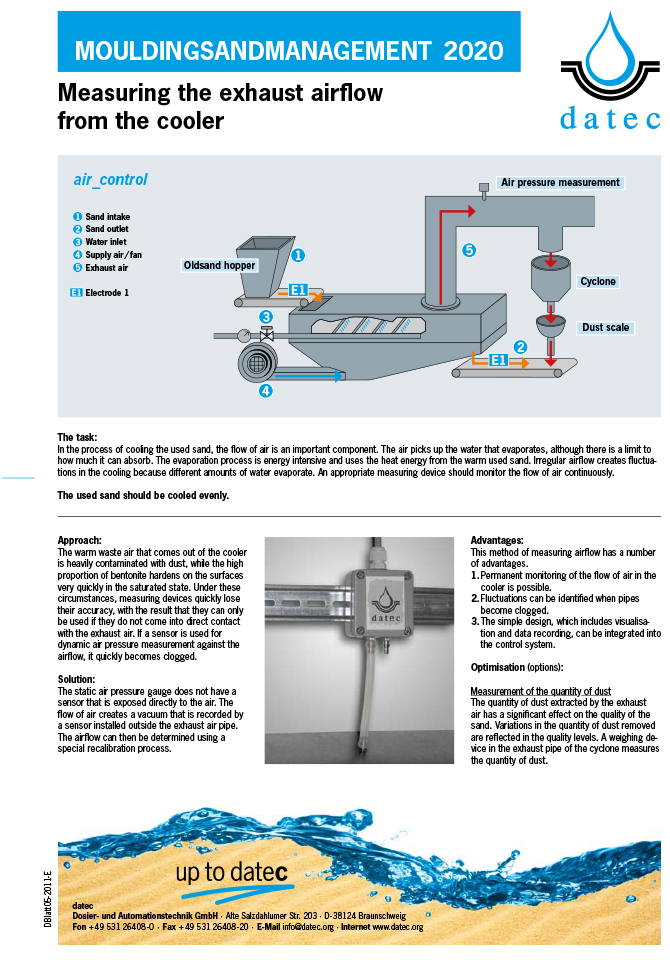

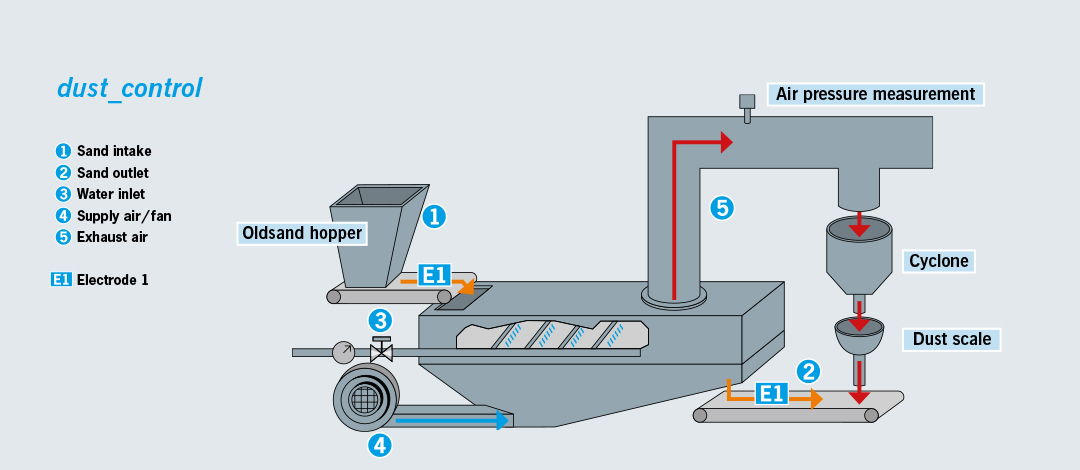

dust_control -Dust collection at the cooler

High transparency

A constant control of the extracted fines from the cooler is possible

Early warning system

Changes are detected as soon as the air volume changes

Quick installation

Simple construction which does not require large installation work

Task

While the used sand is cooled in the cooler, the conveyed air takes on larger quantities of dust and fine particles, which are partially returned to the sand via the cyclone. This dust contains a large quantity of still-active bentonite which is extracted from the moulding material. Often this extraction takes place in an uneven way and therefore has a dominant influence on the fluctuations in strength of the moulding material behind the cooler. This extraction is not to be avoided but should be regular.

Approach

Constant quantification should provide information concerning dust discharge development. As a result of moisture in the air and higher temperatures, optical procedures cannot be used. On the other hand, weighing the cyclone discharge allows definitive quantification.

Solution

Container scales are built in under the cyclone discharge in the downpipe. Each minute the scales are filled, the weight value is recorded, and the scales are then emptied. Corresponding display processing and documentation permits both online observation and later evaluation in order to facilitate improved comprehension of the context. Optionally, a suitable discharge device can be placed under the scales in order to bring only some elements back into the used sand in a targeted manner for the sieve line control system, and to remove the rest.