Shake-out drum

Additional cooling with shake-out drums

Perfect cooling effects

Demand-driven water addition for cooling and Aufnetzung

Controlled addition of water

Avoidance of critical extra water

Non-contact temperature measurement

Each unpacked bale / case is captured with its temperature

Task

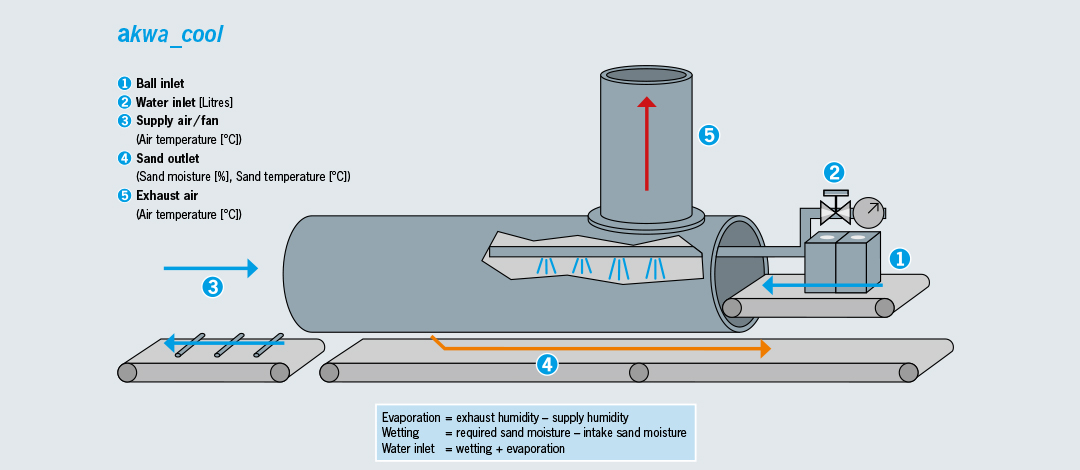

Complete separation of sand and iron takes place after shaking out in the drum. Cooling should also take place in the drum. Water must be added moderately, as the final sand and iron separation takes place at the exit to the drum. The sand is discharged through a sieve whilst the castings are carried over it. No measurement equipment can be accommodated in the drum.

Used sand should be cooled as much as possible.

Approach

As in customary coolers, the cooling process used is evaporative cooling. Evaporation of water in air requires a great deal of energy. This energy is derived from the available thermal energy in the used sand. This energy extraction significantly influences the cooling process. The air flowing through the drums takes on the evaporated water. The through-flow characteristics are not very strong, meaning that evaporation and cooling have only a limited effect.

Solution

Water must be added only very moderately, to prevent the used sand from clumping, which would prevent it from flowing through the sieve. Used sand moisture cannot be measured, as there is no suitable measurement point without the risk of destruction. The core element of adapted water dosing is determining the evaporation behaviour in the exhaust air, as well as the model-specific determination of the model currently in the shake-out drum and its temperatures, which are measured remotely.