by Wolfgang Ernst (datec GmbH), January 2021

30% higher sand throughput after retrofit of controls

A comprehensive renewal of the PLC control, the power unit and also the measurement technology resulted in significant improvements in the sand processing of the Dutch Aluminum Gieterij Oldenzaal in Oldenzaal, near the German border.

“Our controls were getting on in years and individual devices were no longer working properly. We had to act. ”Danny Vreriks, Process Engineer and Planner, explained the investment measure. “A repair was no longer worthwhile - we had switched off the moisture measurement / water metering and added the amount of water manually using a fixed value. The weighing of the used sand was too imprecise and we always had too much sand in the mixer and had to significantly reduce the batch weight. "

After it became clear that the innovation reserves for sand preparation were in the control and measurement technology package Sandplant_control, the company decided on a large and comprehensive solution with us, the company datec.

Managing director Dennis Eekers wanted to implement 4 goals:

• Safe, state-of-the-art control

• Significant improvement of the sand quality through even sand values

• Reduction of electrical energy consumption

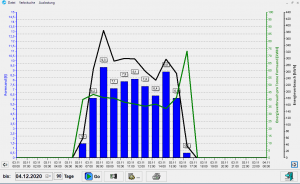

• Traceability and evaluation of the sand values through long-term storage of the batch values with the help of SPC programs

The exchange of the control could of course not be accomplished like a tire change, because it was a clear improvement and the latest technology should be used. Not only was the latest PLC and a completely new power unit installed, but the weighing technology and moisture-dependent water metering with our datec system akwa_mix were also renewed. An important step towards improving quality was the installation of the ROTOCONTROL RTC 107 on the mixer for online molding material testing in the mixing cycle with direct correction of compressibility and compressive strength.

With DView, the operation and display was relocated from the old control room to the molding system. The most important operating states and measured values are displayed online with a sufficiently large screen visualization. The molding machine operator can change the recipe himself very quickly when changing models. Faults in sand processing are displayed immediately and can be remedied from there.

Even with an older mixer, the investment is worthwhile

Hardly any modifications were made to the system itself during the investment; the new electrical equipment alone enabled significant improvements to be achieved. The original batch weight of 200 kg could be increased to 260 kg and at the same time the uniformity of the sand could be increased. The compressibility fluctuates only slightly, namely 1.5% in the 1st standard deviation.

In the spirit of the general energy-saving discussion, sand processing was also implemented with the Energy_control program module. An operating mode that automatically stops the sand processing when idling is detected and starts up again when sand is required. Although there are no long-term secured data with reliable findings, a conservative estimate is based on savings of at least 10%.

Click here for the subsequent article.