MOULDINGSANDMANAGEMENT

Mouldingsandmanagement System 2020: Superlative moulding sand

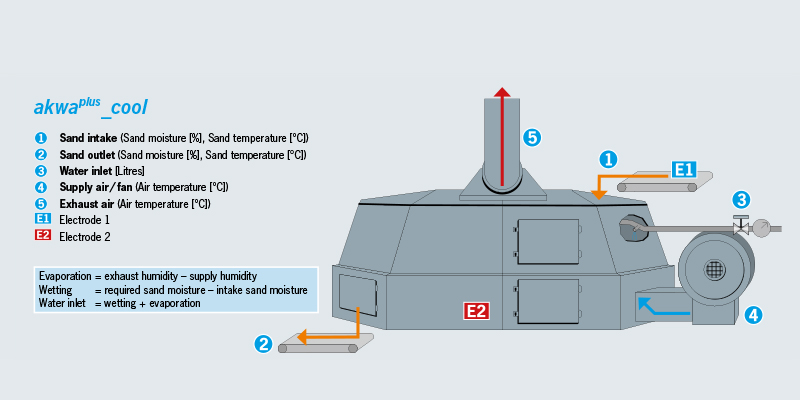

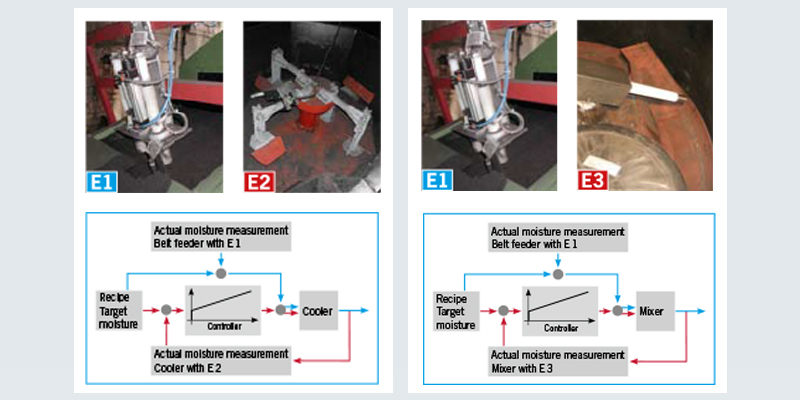

Moulding sand management involves adding water in a targeted manner at the cooler stage. Using a combination of moisture measurement prior to the cooler stage and a temperature measurement point in the cooler exhaust air, an initial quantity of water is determined and measured out. With a second moisture measurement stage in the cooler a regulator is supplied which controls the final moisture level.

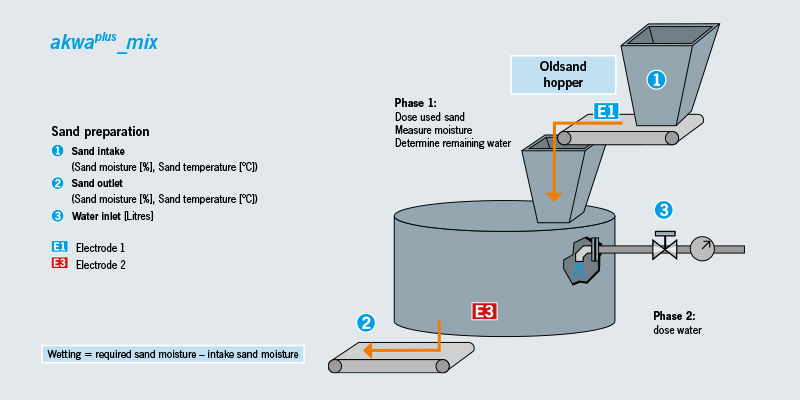

On the used sand hopper’s discharging belts, the inbuilt moisture and temperature measurement electrodes are used to determine the water requirement and to counteract evaporation.

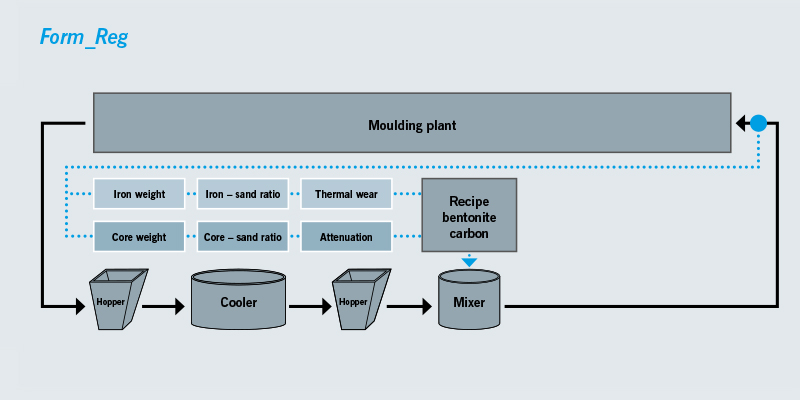

The addition of binding materials can be determined preventively or casting-oriented – both methods permit automatic formulation control with unmanned operation. The regulated wear factors for bentonite and anthracite form the basis of this. The bentonite requirement is determined by the quantities in the container for cast iron and reclaimed core sand.

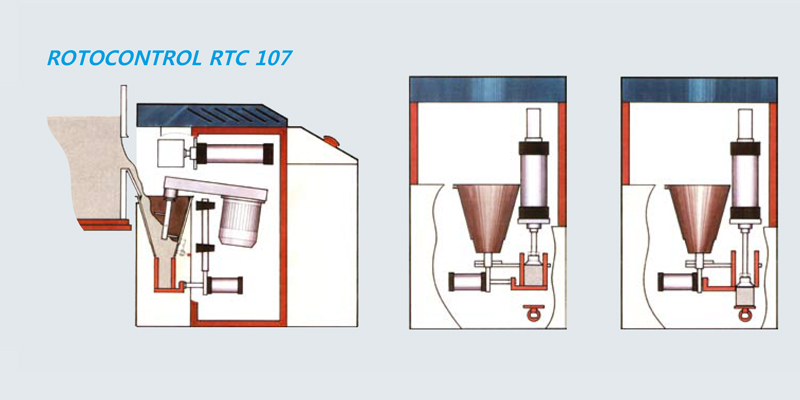

Learn more about Rotocontrol RTC 107

The automatic RTC 107 sand inspection system is installed onto the mixer and takes sand samples during the mixing cycle in order to measure its compressive strength and compactibility. Where variances exist, additional corrective water can still be dosed within the same batch.

Learn more about our moisture electrodes

As part of our moisture measurement, the most diverse electrodes are used, which we manufacture ourselves in an application-oriented way. The repertoire ranges from tripolar electrodes on the belts through to self-cleaning electrodes in the mixer.

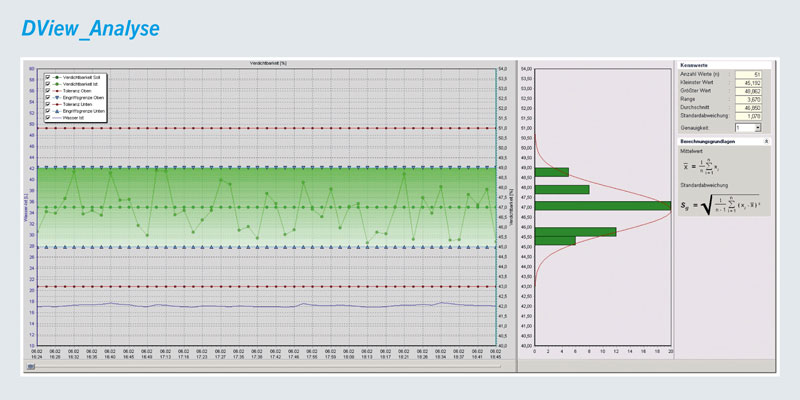

Learn more about DView_Analyse

With the help of statistical evaluation, collected operating data from the batch protocols can be visualised. In this way, long-term insights into the way the plant functions can be obtained in order to continue to optimise the moulding sand.

The term “Mouldingsandmanagement” introduced by datec describes the continuous monitoring of the indicators which are critical for quality in casting procedures using precise and appropriate measurement instruments. The goal of moulding sand management is to minimise errors related to moulding sand during casting, thus reducing waste. The installation of the various modules of the Mouldingsandmanagement System 2020 lead to synergies in an “automatic” way, in the truest sense of the word. The configuration of the individual dosing mechanisms permits a high-grade adjustment of individual batches based on the castings.